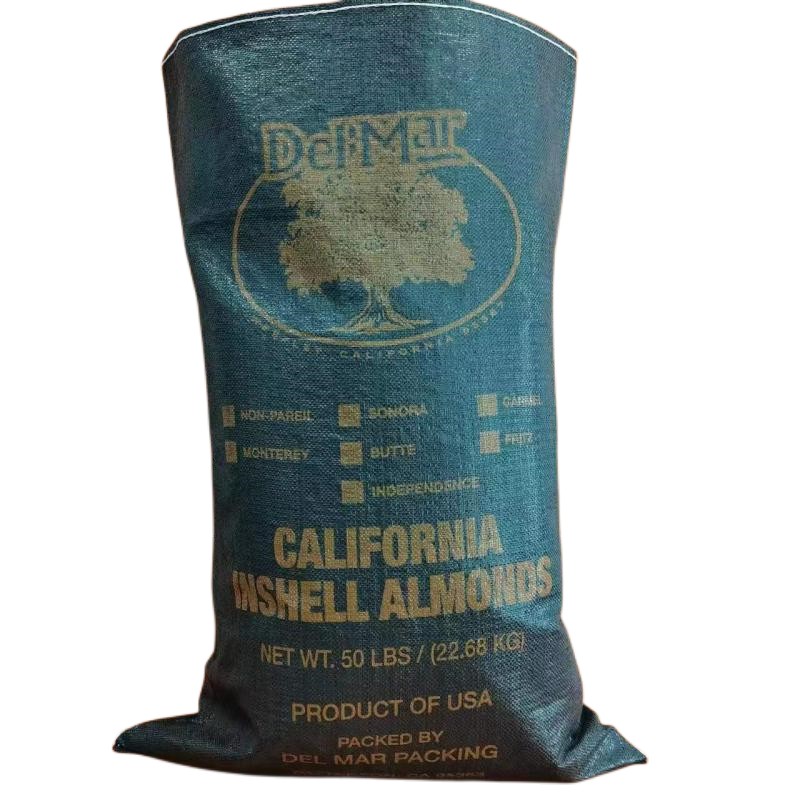

Custom Printed 46*76cm PE inner pp woven bag

46*76cm weight 100g PE inner pp woven bag

PE inner pp woven bag production equipment and process is relatively simple, low investment in equipment, very widely used.

Free samples we can offer

-

Sample1

size

-

Sample2

size

GET A QUOTE

Detail