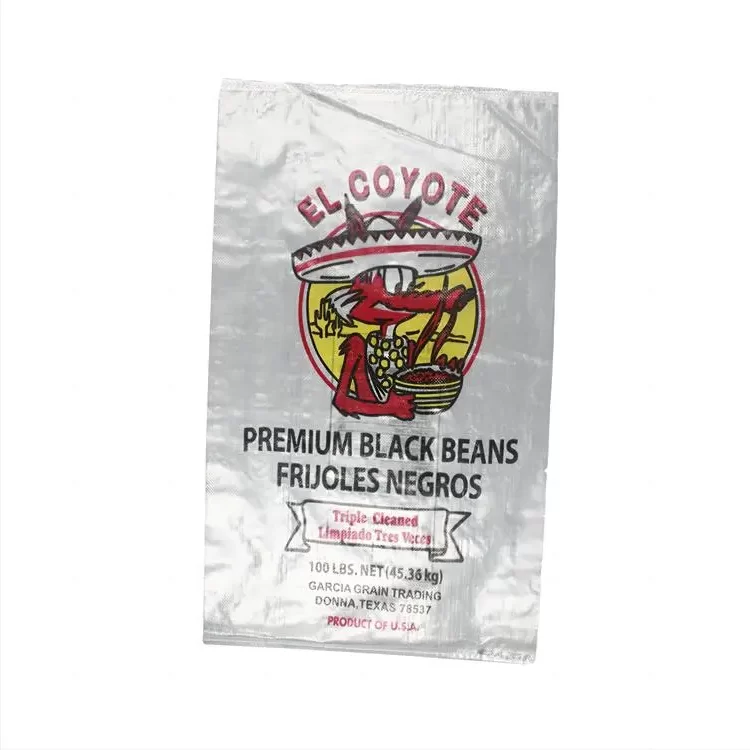

Recyclable transparent woven polypropylene bags for packing fruits and vegetables

Transparent pp woven bag

Free samples we can offer

-

Sample1

size

-

Sample2

size

-

Sample3

size

GET A QUOTE

Detail