Supply reusable kraft paper bag for packing cement and industrial materials

Kraft paper bag

Free samples we can offer

-

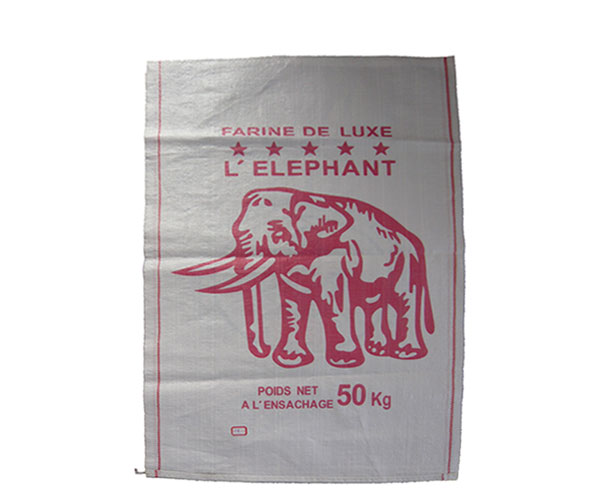

Sample1

size

-

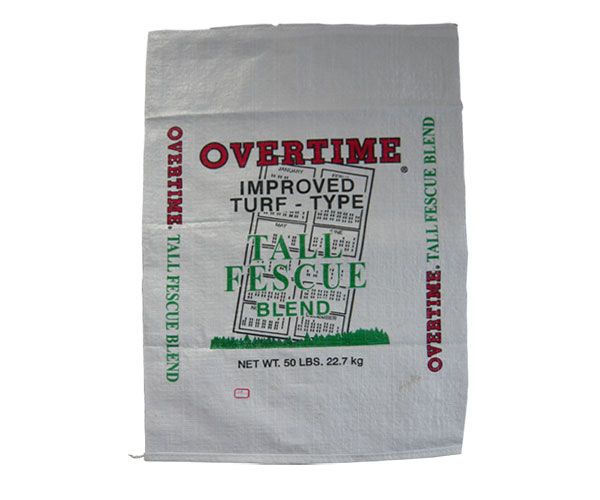

Sample2

size

-

Sample3

size

GET A QUOTE

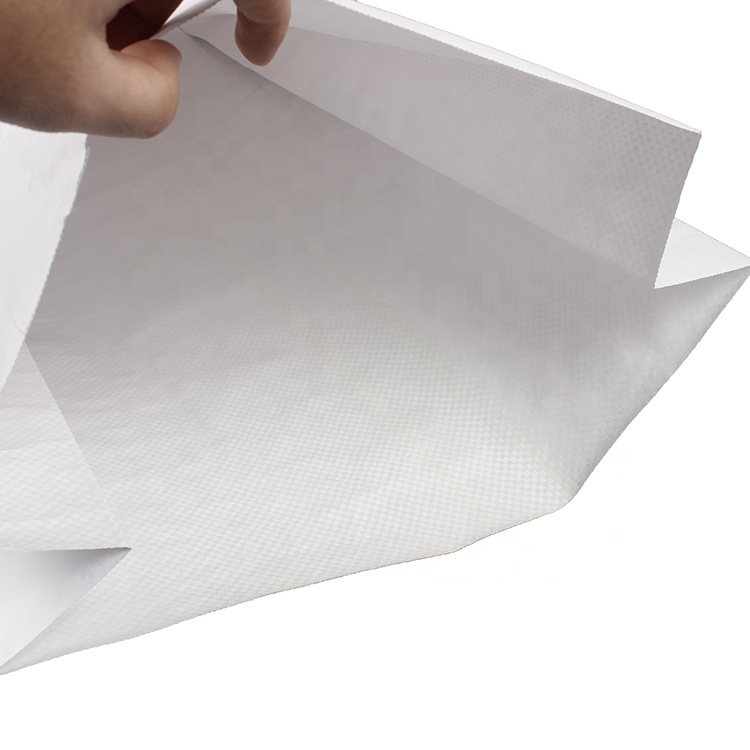

Detail