Key Differences Between IBC and FIBC

Material and Construction

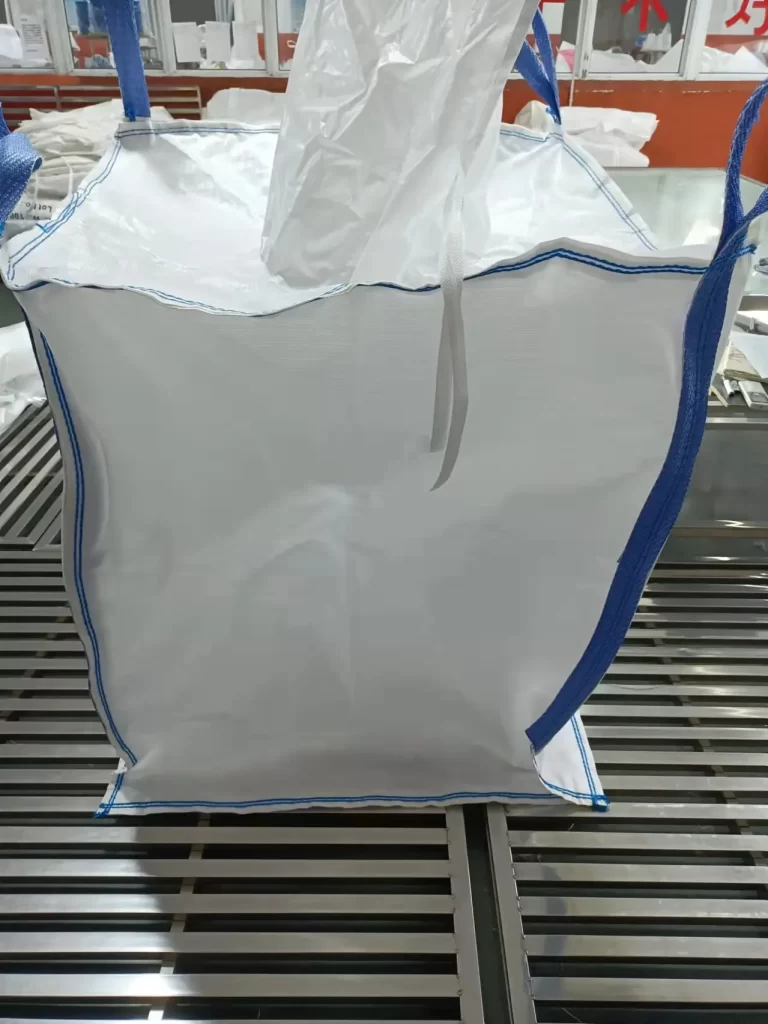

One of the primary differences between IBC and FIBC is the material and construction. IBCs are typically made of rigid materials such as HDPE or composite materials, while FIBCs are made of flexible woven polypropylene fabric. This fundamental difference in construction makes IBCs more suitable for liquids and powders, while FIBCs are better suited for dry, flowable products.

Handling and Transportation

IBC containers are designed to be lifted and moved with a forklift or pallet jack due to their rigid construction and integrated pallet base. On the other hand, FIBCs are often equipped with lifting loops that allow them to be hoisted by cranes or forklifts, making them more versatile for transportation and handling in various settings.

Storage Efficiency

When it comes to storage efficiency, FIBCs have the upper hand. Their collapsible design allows them to be folded flat when empty, minimizing storage space requirements. IBCs, on the other hand, have a fixed rigid structure that takes up more space when not in use.

Product Compatibility

The choice between IBC and FIBC also depends on the type of product being transported or stored. IBCs are ideal for liquids, chemicals, and powders that require a rigid and secure container. FIBCs, on the other hand, are best suited for granular or flowable products that can adapt to the flexible nature of the bag.

Cost Considerations

In terms of cost, FIBCs are generally more cost-effective than IBCs due to their lightweight construction, collapsible design, and lower material costs. Additionally, FIBCs offer savings in transportation and storage expenses due to their flexibility and space-saving capabilities.

In summary, while both IBCs and FIBCs serve the purpose of transporting and storing bulk goods, they are designed for different types of products and have distinct advantages based on their material, construction, handling, storage efficiency, product compatibility, and cost considerations. Understanding the differences between IBC and FIBC is essential for selecting the right container that meets your specific requirements for safe and efficient transportation and storage.

Whether you're dealing with liquids, powders, or granular materials, choosing the right container can make a significant impact on the overall logistics and cost-effectiveness of your operations. By weighing the unique characteristics of IBCs and FIBCs against your specific needs, you can make informed decisions that optimize your supply chain management and enhance the safety and integrity of your products during transit and storage.