Recent Post

- The production process of pp woven bags

- What are the common characteristics of pp woven b…

- New national standard for woven bags

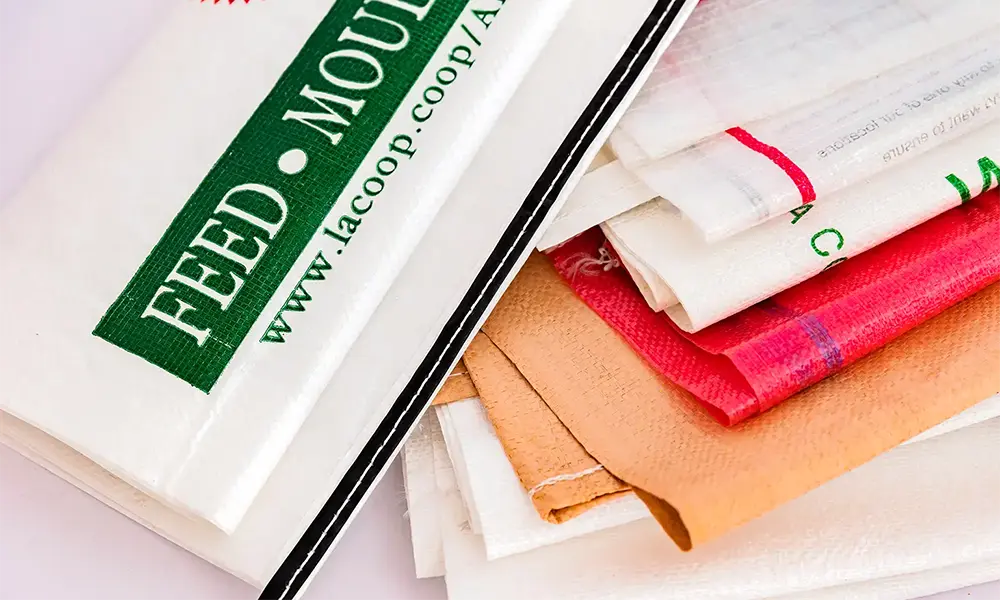

- Types and uses of woven bags

- What printing methods and printing steps are used…

- What are the uses of plastic pp woven bags?

- Anti-ageing woven bags and anti-ageing woven bags…

- The process of laminated woven bags